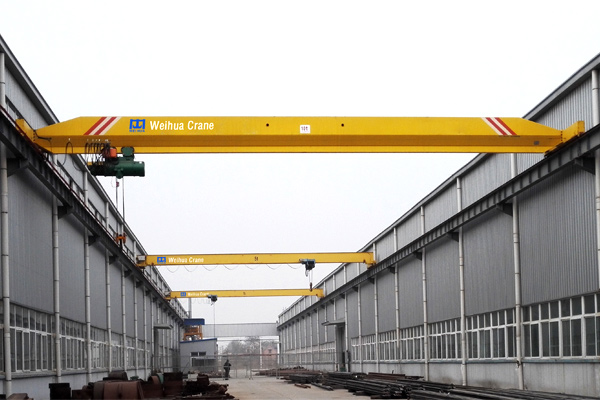

General safety inspection items during crane operation

In order to ensure the safe operation of the bridge crane, some safety routine inspections are required during the operation of the crane. The inspection items and key points are as follows:

(1) Lift height limiter, travel limit switch and interlocking mechanism are normal, safe and reliable.

(1) Lift height limiter, travel limit switch and interlocking mechanism are normal, safe and reliable.

(2) The main components meet the safety requirements: the opening increase is less than 15% of the original size, the torsional deformation is less than 10%; the wear of the plate hook bushing is less than 50% of the original size, the wear of the plate hook spindle is less than 5%, no peeling Burrs, welding repair. Hook hangers and pulleys have no obvious defects. Steel wire rope surface wear, corrosion less than 40% of the diameter of the wire, broken wire within a pitch is less than 10% of the total number of wire, no breakage, no significant thinning, no core removal, corner twisting, extrusion deformation , annealing, burning phenomenon. The connection of the end of the steel wire rope and the fixed clamp, pressure plate and block block are well connected without looseness, the pressure plate is not less than 2 and the number of clamps is not less than 3. The reel has no cracks, no looseness in connection and fixation; the wall wear is less than 20% of the original wall thickness; the safety roll is no less than 2 turns, and the ratio of the diameter of the reel to the wire rope meets the requirements. The balance wheel is fixed and the wire rope should meet the requirements. The brakes are free of cracks, no looseness, and no serious wear. The brake gaps are equally sized on both sides and have sufficient braking force. The brake band wear is less than 50% of the original thickness.

Through the routine safety inspection of bridge cranes, it has played a significant role in eliminating personal accidents, reducing equipment accidents, improving equipment operation rates, and reducing maintenance costs.

>> Previous:Analysis of the causes of wear of wire rope electric hoist gears

>> Next:The method of reducing the heat of the vibration motor and its preventive measures

>> Next:The method of reducing the heat of the vibration motor and its preventive measures

Contact us